Our Manufacturing Facility

Our fully integrated manufacturing facility is designed for efficiency, scale, and quality. From fabric sourcing to final packing, every stage is managed in-house by skilled professionals and modern machinery. With a strong focus on design flexibility and quick turnaround, our infrastructure supports both premium and affordable product lines, ensuring we meet diverse customer and market needs with consistency and care.

Raw Material

At Rajnandini, quality starts at the source. We carefully select premium raw materials—ranging from cotton, poly cotton, rayon to blended fabrics. Each fabric is selected for its comfort, durability, and visual appeal, forming the base of our signature style and craftsmanship. This meticulous selection process ensures that every garment reflects our commitment to quality, versatility, and value.

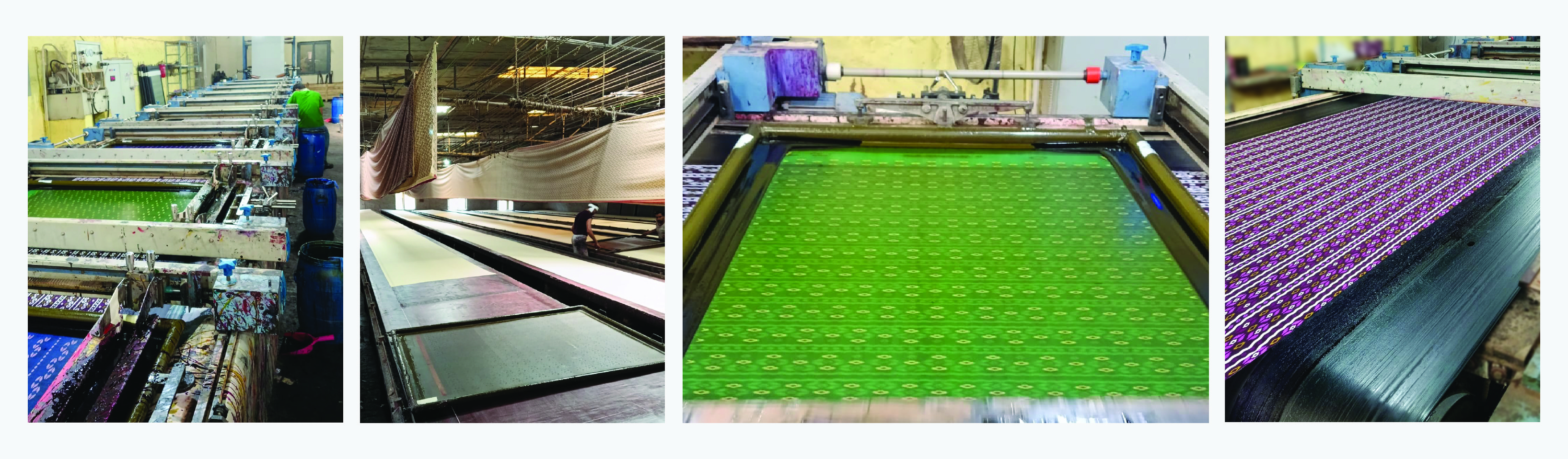

Material Prints

Our Prints bring designs to life with high-quality screen, digital, and rotary prints. From bold patterns to subtle motifs, we ensure vibrant colors, sharp detail, and long-lasting prints on a wide range of fabrics. This enables fast turnaround and full creative flexibility for seasonal and custom collections.

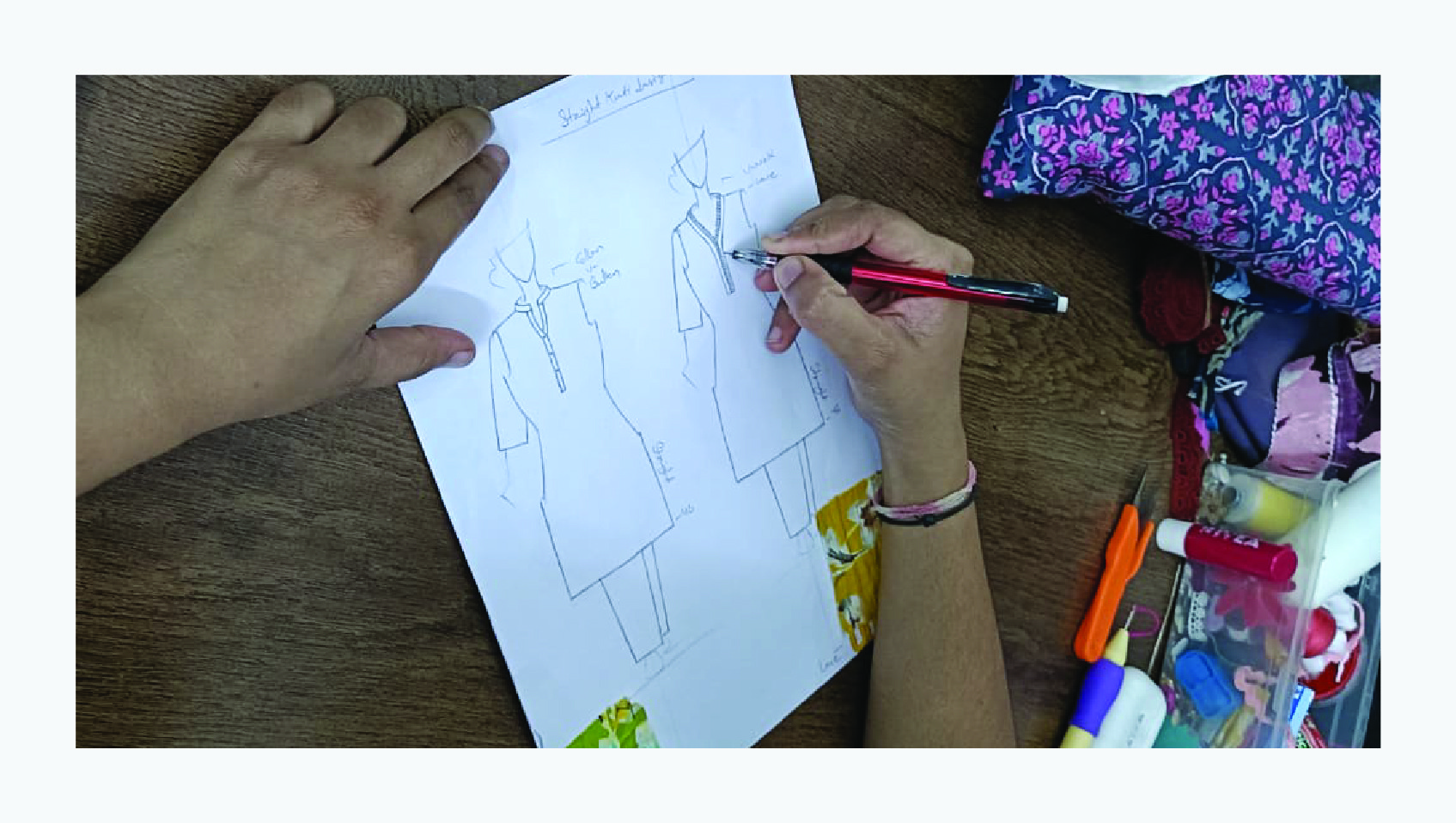

Design Sketching

Every garment begins as an idea brought to life through hand-drawn or digital sketches. Our in-house designers blend ethnic aesthetics with modern silhouettes, capturing trends, fabric flow, and wearability. These sketches are the first blueprint before sampling and production.

Pattern Making

Our skilled design and sampling team creates precise patterns that ensure a perfect fit and flow across all garment types. Using a mix of manual drafting and digital tools, we develop patterns that align with current trends, fabric behavior, and production efficiency, laying the foundation for high-quality, consistent garments at scale.

Layering & Cutting of Garment

We use precision layering and cutting techniques to ensure minimal fabric wastage and consistent sizing. With a mix of manual expertise and machine accuracy, our team prepares fabric stacks and cuts patterns in bulk—ensuring speed, efficiency, and quality in every piece.

Stitching

At Rajnandini, stitching is where design takes form. Our dedicated unit, equipped with advanced industrial sewing machines and a team of highly skilled tailors, ensures each garment is crafted with precision. We have a range of stitching techniques tailored to fabric types and garment styles, on fit, finish, comfort, and a polished final product.

With a daily production capacity of 3800-4000 pieces, we efficiently meet high-volume demands without compromising on quality.

Handwork & Embroidery

We enhance our garments with intricate handwork and embroidery, adding traditional charm and artisanal value. Our skilled artisans create detailed embellishments—from thread work and mirror work to sequins and beads—tailored to each design. This in-house capability allows us to offer premium, handcrafted finishes that elevate the final look.

Thread Cutting

At Rajnandini, stitching is where design takes form. Our dedicated unit, equipped with advanced industrial sewing machines and a team of highly skilled tailors, ensures each garment is crafted with precision. We use a range of stitching techniques tailored to fabric types and garment styles, focusing on fit, finish, and comfort, ensuring a polished final product.

Quality Checking

Every garment undergoes a thorough quality check to ensure it meets our standards for stitching, fit, finishing, and presentation. Our dedicated QC team inspects each piece to deliver flawless, ready-to-wear products to our customers.

Ironing

Each garment is steam-ironed to ensure a crisp, wrinkle-free finish. This final touch enhances the garment’s presentation and prepares it for packing and delivery in perfect condition.

Branding & Packaging

Our packaging process reflects our commitment to quality and brand identity. Each garment is neatly folded, tagged with SKU labels, and packed in branded, tamper-proof bags. We ensure clean presentation, product protection, and easy inventory management—ready for retail or direct delivery.

Order Processing & Dispatch

Our dispatch team ensures the timely and accurate delivery of every order. Once packed, garments are systematically sorted, scanned, and handed over to reliable logistics partners for domestic and international shipping. With SKU-based tracking and organized workflows, we maintain efficiency in handling both bulk and direct-to-customer shipments

Sewing Machinery

At Rajnandini, our commitment to precision and quality is supported by state-of-the-art sewing machinery. From basic stitching to advanced processes, our machines ensure efficiency, consistency, and a premium finish for every garment. With 150+ machines, we produce 3800-4000 pieces of complete garments daily.

Types of Machine Quantity

Auto Lock Sewing Machine 140

Over Lock Machine 17

Buttonhole Machine 1

Button Stitch Machine 1

Thread Cutter Machine 5

Factory Machinery

Our modern manufacturing facilities are equipped with a comprehensive range of high-performance machinery to streamline garment production from start to finish.

Types of Machine Quantity

Straight Knife Cutting Machine 10

Iron Machine 11

Boiler 6

End Cutter Machine 5